|

New Products

·Glitter heat transfer vinyl use high-end PET which cut into same size materials through precision machine ,then made into vinyls. Description: Glitter heat transfer vinly use high-end PET which through precision machine devided into same size materials,then made into vinyls.these high-temperature-resistance PET vinyls will turn into glitter heat transfer vinly with hot melt glue and release glue.

Main Feature: ·Glitter heat transfer vinyl use high-end PET which cut into same size materials through precision machine ,then made into vinyls. ·The stereo sense is good,and glossy light,matting hand-feeling is a the biggest difference from other heat transfer vinyls. ·Doesn't need making plate,it will save much time and cost.

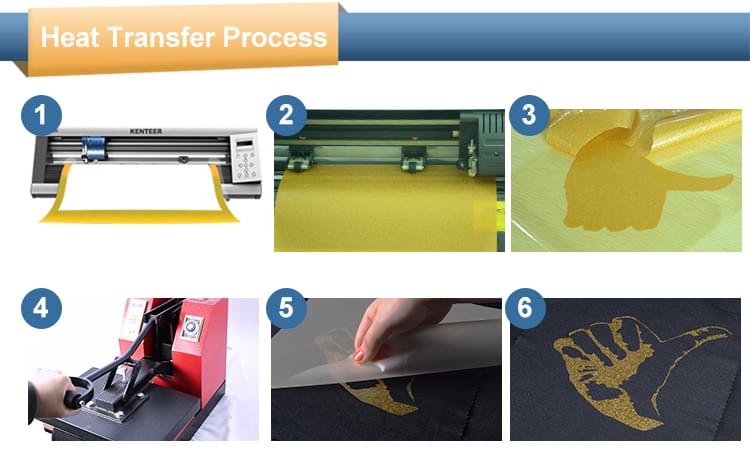

Instruction: ·Use cutting plotter divided into the shapes in need, tear away the film, cut depth between 10-30micron,cutting pressure 160-170gf is the best. ·Tear away the protect film,then transfer the picture cut onto fabrics through heat press machine. ·Transfer temperature 150-160degrees,10-15s,transfer pressure 20-30 LB. ·Peel the protect film after it turned cold.

Attention: ·The expiry date is within 12 months. ·try the simple then produce in massive. ·Seal the rest stickers,you should dry the products,don't let them in rainy day.

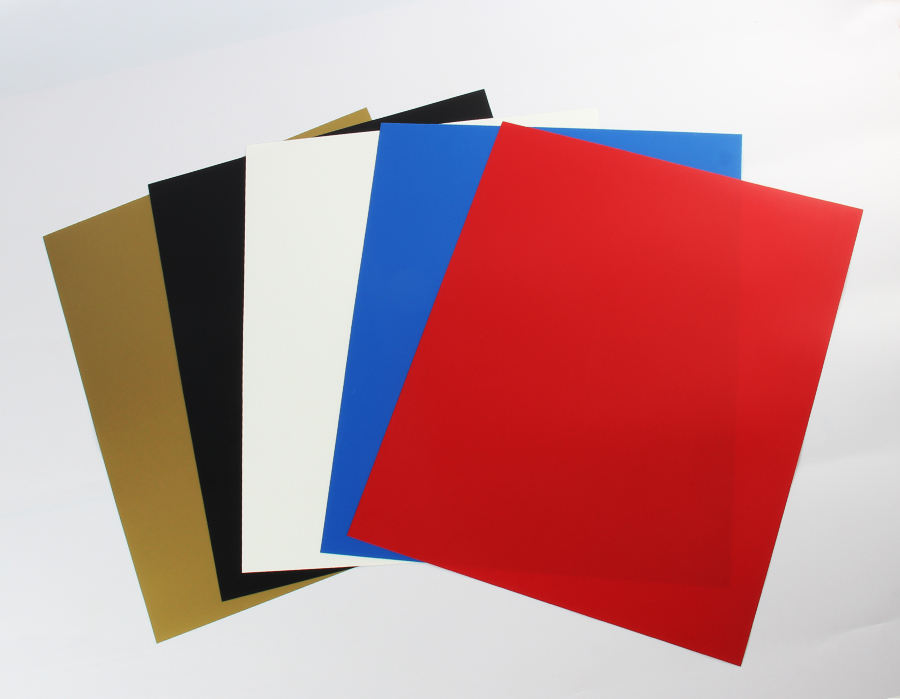

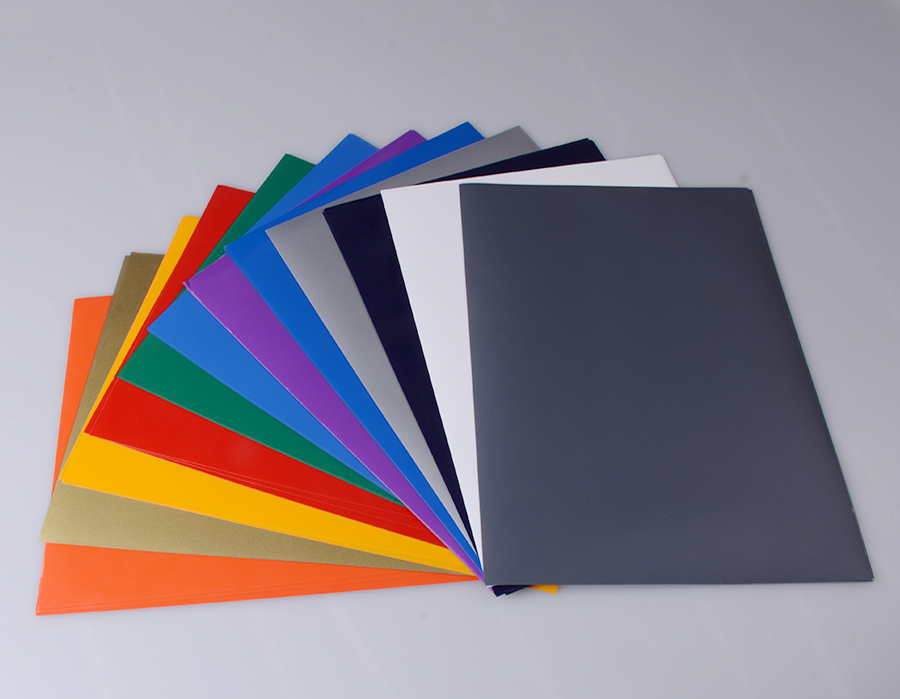

Similar Products

|

||||||||||||||||||||||||||||||||||||||||||||||||